8 questions to answer before shopping for a new fume hood

The process of finding the right fume hood can be a little complicated if you don't know the right questions to ask. You can save yourself a lot of trouble if you know the answers to these questions when you start shopping.

1. What size of fume hood do you need?

Fume Hoods and enclosures vary in width from 2’ to over 12’. They can be from 18” tall to over 12’ tall. Knowing what size you require will help you narrow down what type of hoods to consider.

2. What chemicals or particulates are going to be used in the Fume Hood?

There are general hoods, ductless hoods, powder hoods, acid hoods, explosion proof hoods and many more specialty hoods. Identifying the chemicals that will be used in the hood as well as the particulates and chemical volumes and methods that will be performed in the hood will help to determine which type of hood best fits the application. Also along these lines, will hot plates or other heat producing items be used in the hood?

3. How important is the cost of operation?

The cost of operation will be determined by the amount of tempered air that is exhausted from the room. This cost can vary greatly depending on the hood type. Some hoods are high performance so can be operated at lower face velocities than traditional hoods. Some hoods are ductless therefore do not exhaust any air out of the room while others require large volumes of air to be exhausted out of the room in order to maintain containment. Consult your safety officer.

Accessories such as automated sash sensors can be added to a hood to reduce operating costs. You should study your budget and determine if you are interested in spending a little more in the initial purchase of the hood in order to save thousands of dollars over the life of the hood. Balancing purchase price and operation costs should be given much consideration throughout your hood selection process.

4. What service fixtures are needed in the hood?

There are many types of services and accessories that are typically found in a hood. Vacuum, water, and gas lines are the most common service fixtures added to hoods, and airflow monitors, sash stops and auto sash returns are the most common accessories.

Ask yourself how many service fixtures you will need and where to locate them. How many electrical outlets? Is a sink needed and what is the desired placement?

Airflow monitors are recommended. What type is best for your lab--simple red light/ green light indication or digital airflow readout?

Do you want a sash stop to keep the sash in the safest operating position and reduce operation costs?

5. Where are you going to place the fume hood?

Where in the lab will the hood be placed is an important question. These considerations determine where a hood can be placed:

Is there an available duct run in the building?

Is the hood out of foot traffic?

Are there any cross drafts or competing air patterns that will affect containment?

Where are the emergency services such as a fire extinguisher or washdown shower?

What is the workflow pattern in the lab?

6. On what are you going to place the fume hood?

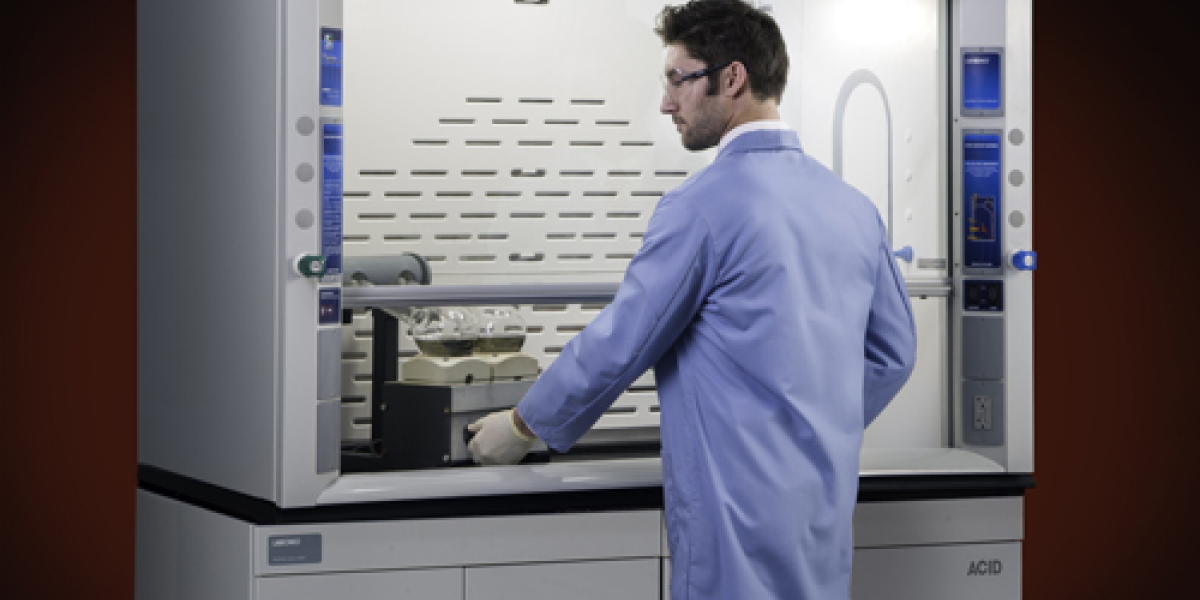

Is there available existing bench space? Do you need to place the hood on chemical storage cabinets where acids, solvents and general chemicals can be stored safely? Most hoods require a specifically designed work surface. Do you want your work surface to be dished to contain spills or to include a sink?

7. Do you need a blower to exhaust the fume hood, and what size of blower do you need?

A hood is simply an enclosure designed to contain the fumes and provide a safe working environment. It is the blower that does the work by moving air ensuring proper containment. There are external roof-mounted blowers and internal blowers. Knowing the types of blowers your company, institution and building codes require will help you decide the type of exhaust blower to buy for your hood.

The proper sizing of a blower is critical to the effectiveness of your fume hood. Please seek the advice of an expert when choosing the blower size. Information that is needed to size the blower includes fume hood model, duct diameter, length of the duct run, number of 45° and 90° turns in the duct run and type of weather cap that will be used.

8. Who is going to install the fume hood?

Proper installation is very important in fume hood systems. Blower adjustments may need to be made, electrical and service connections are critical and a final certification of airflow and containment should be done.

With these questions answered, you'll be prepared to make an expert decision.

| chevron_left | Lab comfort: Is it a cultural thing? | Articles | Video: AtmosPure Re-Gen Gas Purifier installation made easy | chevron_right |