Energy efficiency explained: Potential savings of real labs

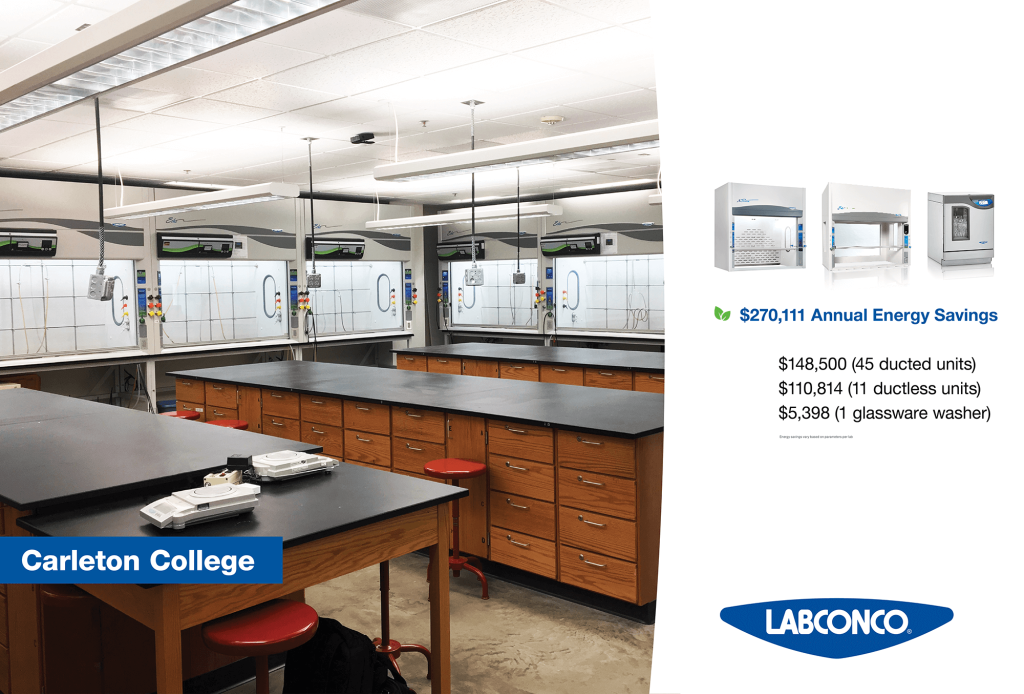

Here are a few high level case study savings figures associated with proper design process, and efficient product selection.

Labconco Links

- Why fume hoods are energy consumers, and what modern hoods and controls can do: Reducing fume hood energy consumption - Labconco

- What drives energy consumption in laboratories The Right Fume Hoods: The Building Blocks of Zero Net Energy (ZNE) Lab Design - Labconco

- Case study on ductless hoods Carleton College finds flexibility, safety in filtered fume hoods - Labconco

Here is a link to a performance contracting company. There are others of course, but this should yield perspective on how this works. Willdan Home

Energy Assessments

Below is an example of an energy assessment we can perform in certain applications. The example below was for a project in the Boston area, and was for 73 hoods comparing Labconco to another popular hood in the market.

This is in regard to your request for an energy assessment of equipment proposed.

There is a lot of information included in the attached pdf, and I have included all my math and citations to assist the reader in understanding. This is purely an estimate of energy cost saved and reserved mechanical system capacity if using the efficient Labconco products. I look forward to the potential of updating this to more accurately reflect actual operating conditions as they become known, and am open to an analysis of my spreadsheet during a real-time consultation.

Assumptions

- Mechanical plans indicated cooling with chilled water. I assume Central Plant, Air cooled screw chillers, EER 9.5, IPLV, 14.6. This can be adjusted if we learn the operating efficiency of the CPU.

- We see the VAV system is to maintain a face velocity of 80 fpm from the Fume Hood specifications, we are assuming maintenance of that face velocity at all sash positions.

- Sash closed minimum volumetric rate is assumed 375 ACH (Ref Note 1 below).

- Assuming operating hours in the following conditions (These can be adjusted after consultation with EHS).

|

Sash |

Average Hours per |

|

Position |

week |

|

Closed |

112 |

|

18" |

52 |

|

28" |

4 |

- We have assumed a natural gas cost of 0.694 ($/therm) referenced from eversource.com, which is likely conservative, is specific to Boston, MA, and this can be updated if we learn the true utility cost.

- We have assumed an electricity cost of 0.1384 ($/kWh) referenced from electricitylocal.com specifically for Boston, MA commercial customers (lowest listed rate), and this can be update if we learn the true utility cost.

- We have assumed an annual increase in energy costs of 5.45% per the World Bank Natural Gas Price Forecast.

Mechanical System Capacity Reserved

We do not know the actual assumed fume hood diversity, so I collected required volumetric rate requirements associated with the operating height (18") sash opening and 80 fpm face velocity from the baseline manufacturer, as well as from Labconco's measured volumetric rate data. Because Labconco hoods require a lower volumetric rate to achieve your face velocity requirement, and because there are 73 hoods involved in the assessment, the combined mechanical system capacity (supply and exhaust air) preserved by using a more energy efficient hood is enough to operate four additional 4' fume hoods. I will stress that this is a comparison scenario of all hoods with sashes at their operating height. This could potentially translate to the freedom to add more ventilation containment devices in the future.

|

Mechanical system capacity reserved |

|

2525 |

Volume of Air Difference

As part of assessing the dollars saved in energy, I needed to break down the total difference in air consumed by the building. This is from raw outside air, to tempered air where capacity is removed or added to achieve 70 degrees and 50% humidity, moving the air to and through the lab space, sending it through the hoods, and finally blasting it vertically away from the building at 3000 fpm. So this is a good place to emphasize that we are comparing two sets of hoods, of the same size, on a VAV type mechanical system, same sash position durations, same operating face velocity, and both with 375 internal ACH with the sashes closed. This is already an efficient set up with either hood, but if they were all Labconco hoods, the building mechanical system will not be burdened with moving and conditioning 1.6 Billion cubic feet of air each year. Cubic Feet of air saved per year (CF/Y) 1,601,895,360

|

Cubic Feet of air |

|

1,601,895,360 |

Energy Dollars Saved

The figures below, encompass all of the details associated with the figures above, and incorporate weather/climate conditions specific to Boston, utility rate data specific to Boston, anticipated future cost of energy, and mechanical system efficiency data specific to the HF Condensing Boilers employed.

|

Dollars Saved, |

Dollars Saved, |

Dollars Saved, |

Dollars Saved, |

|

$43,413 |

$242,048 |

$557,647 |

$969,145 |

As in all cases, in order for these savings to be realized, building commissioning and air balancing is critical. Lastly, though I believe the methodology to be sound, this must only serve as an estimation, as the input variables are but estimates themselves.

Note:

With regard to minimum CFM with the sashes completely closed, we get perspective from NFPA 45. "...hood exhaust airflow should not be reduced to less than the flow rate recommended in ANSI Z9.5, Laboratory Ventilation." This is A7.4.7 in NFPA 45-2019.

Currently the American National Standards Institute (ANSI) AIHA Z9.5 for 2012 (3.3.2, on the “good practices” column) indicates that “minimum fume hood flow rates in the range of 150 to 375 hood air changes per hour (ACH) have been used to control vapor concentrations inside hood”, pending an assessment of specific considerations.

ANSI Z9.5, will stress an assessment of the following when determining this minimum, and this is especially true where you are at the lower end of the typical range.

- Control of ignition sources in the hood: solvent applications should stay below 25% of the LEL in the worst case scenario.

- Design of the hood, the materials used in the hood, and Anticipated Maximum Generation Rates: generation of heat, chemicals, or dust. Any concern of accumulation, corrosion, dissolution, or heat deformation?

- Exhaust Stack Discharge Velocity: recommended 3000 fpm discharge velocity

- Fume Hood Density: Do not reduce the hood exhaust below the minimum needed room ACH

- Need to affect directional airflows: The minimum CFM must not influence the negative pressurization of the room, or labs where directional flow from outside spaces to inside spaces is required.

- Operating Range of the hood exhaust equipment and associated control system

It’s always best to do a complete EHS assessment and determine proper factors of safety with regard to threshold values for exposure, lower flammability and lower explosive limits (typically 25% of LEL/LFL), especially if you are planning to go below 375ACH. ANSI Z9.5 is the best reference for this, but HERE is a link to an article on our website regarding ACGIH methods for performing LEL/LFL assessments.

For heat generation inside the hood, most manufacturers will be able to offer specific guidance on this. If the sash is closed and heat is being generated in the hood, there is a potential for heat effect. This is where the internal temperature of the hood creates a positive pressure differential at the by-pass, and potential reversal of airflow. Preventing heat effect is primarily a function of dilution to keep the interior temperature down, so we would typically recommend staying at the high end of this VAV minimum CFM range for high heat applications, as well as AU (As Used) containment testing.

If there are any hoods of concern, let me know their width and heat output in Watts, and I can give you a minimum CFM recommendation with respect to Heat Effect only.

| chevron_left | The Solvent Cabinet—a Laboratory Super Hero | Articles | VIDEO: Lyo-Works OS for Labconco FreeZone Freeze Dryers | chevron_right |