Biosafety cabinet human factors design

Every job has its own hazards, the majority of which are due to how humans interact with our work environment. Laboratory science is no exception; however, many employees do not associate potential hazards and injuries to the layout and configuration of their work centers.

The field of Human Factors, more commonly known as Ergonomics, is a multidisciplinary approach to understanding the way humans physically interact with their surroundings. Research in this field strives to improve how systems more efficiently, and therefore more safely, integrate with humans.

Biosafety Cabinet Risks

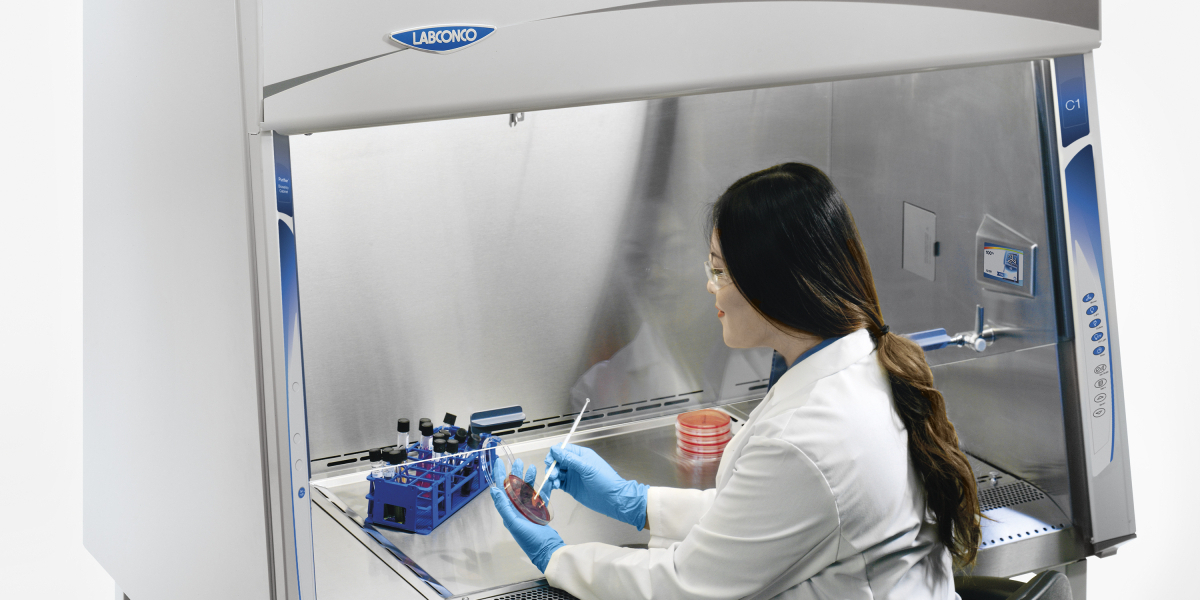

The tools and procedures employed in microbiology attempt to put the researcher in the world of the infinitesimal. Balancing comfort with the need for incredible precision is the main challenge when designing equipment for microbiology lab work. When conducting activities which require a biosafety cabinet, such as pipetting and microscopy involving biohazards, the ergonomic risks are compounded.

There are also intrinsic risks associated with biosafety cabinet (BSC) use. Cumulatively, the common risks accompanying these jobs include:

-

Poor Working Posture – Head bent forward for long periods, raised and/or outstretched arms, fixed postures held for prolonged periods.

-

Upper Limb Disorder Risks – Repetitive actions, awkward wrist/arm posture, forceful actions (including pinching grips).

-

Environment – Space constraints, lighting temperature, vibration, etc.

-

Load – Working with sharp, hot, cold or toxic/hazardous objects.

-

Other Factors – Personnel protective equipment that might make work more taxing.

- Fatigue – An accumulation of multiple risk factors listed above.

Working with most BSCs can put workers at high risk for Repetitive Strain Injuries, or RSIs. Laboratory acquired RSIs often include:

-

Tendonitis and tenosynovitis

-

Rotator Cuff Tendonitis

-

Thoracic Outlet Syndrome (TOS)

-

Carpal Tunnel Syndrome (CTS)

-

Wrist ganglion cysts

- Back injuries

BSC Design Standards

Biosafety Cabinets should be designed, tested and listed to an approved performance standard such as the National Sanitation Foundation’s NSF/ANSI Standard 49 or the European Union’s standard EN 12469. These standards and product listings ensure that BSCs provide a basic safe environment for working with biohazards, provided the cabinet is operating properly. A BSC’s human factors design and end user comfort (features) dictate how an operator works, thus directly affecting their productivity and safety. “Designing tasks, equipment and work stations to suit the user can reduce human error, accidents and ill-health. Failure to observe ergonomic principles can have serious consequences for individuals and for the whole organization. Effective use of ergonomics will make work safer, healthier and more productive” (HSE).

The safety standards have not established requirements for human factors and user comfort specifications. Driven by competition, manufacturers have made great advances by engineering products to increase safety through improved comfort. These design features must be evaluated by researchers, technicians and safety officers. It is of utmost importance for these users to completely evaluate a product for all of the safety, ergonomic and comfort features, as there are vast differences between how each manufacturer approaches BSC design and ergonomic engineering.

Embracing Human Inclination

Building on four decades of ergonomic innovation, the Purifier Logic®+ design team scrutenized every biosafety cabinet on the market and looked to find, design and utilize the best features found throughout the industry. Their work resulted in the development of the most extensive human factors package, Inclination™ Technology, and the MyLogic™ Operating System, released in the early months of 2013.

Keeping the ergonomically sound design of the Delta and Logic as the foundation, the goal of Inclination Technology was to maximize safety through observing and understanding human habits. Modifications that evoke the essence of the human experience were added to the counter-balanced, anti-racking, inclined sash, line-of-sight digital display, ADA compliant cabinet controls, electrical outlets and utility service fixtures.

For safe entry of cords, cables and tubing connecting two devices, one outside of the BSC and the other in the BSC’s work zone, a portal was designed that remained within easy reach of a seated user. These devices keep the connections out of the way in a busy workstation, and protect both the lab and the BSC interior from loss of containment through a vacuum lock system. The Vacu-Pass™ Cord & Cable Portal was first submitted for NSF/ANSI Standard 49 approval in 2012; only after ensuring the design met all three of the above requirements was it formally adopted into BSC design.

Learn about the latest BSC innovations, and see how different BSC Types stack up against one another

Another feature commonly cited as a "safety feature" intrigued and confounded the design team—the internal electrical outlet. Its presence and location in the BSC is designed for human factors. Outlet covers protruding into the interior of the BSCs work zone and utilizing loaded springs are anything but ergonomic. The self-closing mechanisms, required by laboratory design codes, utilize loaded springs that exert significant force on the doors, turning them into high velocity finger traps. To counter this bear-trap like operation, the stainless steel covers’ hinges have been dampened for slow closing execution. Furthermore, the stainless steel electrical outlet covers of the Logic+ are flush mounted, increasing cabinet access and making it easier to clean and decontaminate the cabinet’s interior surfaces.

‘Plug-and-play’ or turnkey devices are the norm in today’s technological landscape. In consumer products, this typically means that the set-up of a device is launched at initial start-up and is a ‘self-guided’ procedure. This idea was not lost on the Purifier Logic+ design team. Building from the digital display employed in the Logic, MyLogic OS utilizes an optimized, multifunction, color display with intuitive programming designed to guide an operator through cabinet set-up, calibration and diagnostic troubleshooting. Using full sentences, MyLogic OS initially guides a new user through Smart-Start™ set-up, allowing for control of the cabinet’s entire operation with simple sash movement. Cabinet status is displayed on the digital display, and utilizing system feedback, a diagram of a BSC highlights areas of the cabinet effected by or causing an alert or alarm condition. This graphic is accompanied by a status message that describes the condition and provides correctional walk-through instructions. Though not recommended, the Logic+ could easily be set-up and operated without ever consulting the Operator’s Manual.

The Culmination of BSC Design

The first Class II biosafety cabinets were developed with the advent of laminar airflow in the 1960s (CDC, 2009). Even though comfort is paramount to the safety of the operator, it took nearly 40 years before the industry’s manufacturers began taking ergonomics seriously. In the time since, BSC design has taken on its own look and feel, with thoughtful regard toward how form and function should meet. However, there exists a paradox in Human Factor and Ergonomic engineering. Greater advances are demanded in a shortened period of time between product releases.

For Labconco, this paradox has been met in diverse ways, but always with the same goals — to provide total comfort, effortless operation & maximum safety. To this end, there is only one road to take — collaboration with laboratory users leading to innovation in design. Invention in BSC human factors design will continue to develop and will have positive impact on safety performance. The way each BSC manufacturer approaches this concept is the underlying reason that biosafety cabinets, when designed to meet just a safety standard, are truly not created equally.

Download the Inclination Technology White Paper

Download the Purifier Logic®+ and Axiom® Brochures

Read "On the Origin of BSCs: The Evolution of Human Inclination Technology"

Works Cited

CDC, 2009. Biosafety in Microbiological and Biomedical Laboratories. 5th ed. Washington, D.C.: National Instute of Health.

HSE, n.d. Health and Safety Executive: Human Factors Design. [Online] Available at: www.hse.gov.uk/humanfactors [Accessed 22 January 2013].

| chevron_left | Improving Energy Efficiency in the Lab | Articles | Type C1 Biosafety Cabinets: What's Different? | chevron_right |