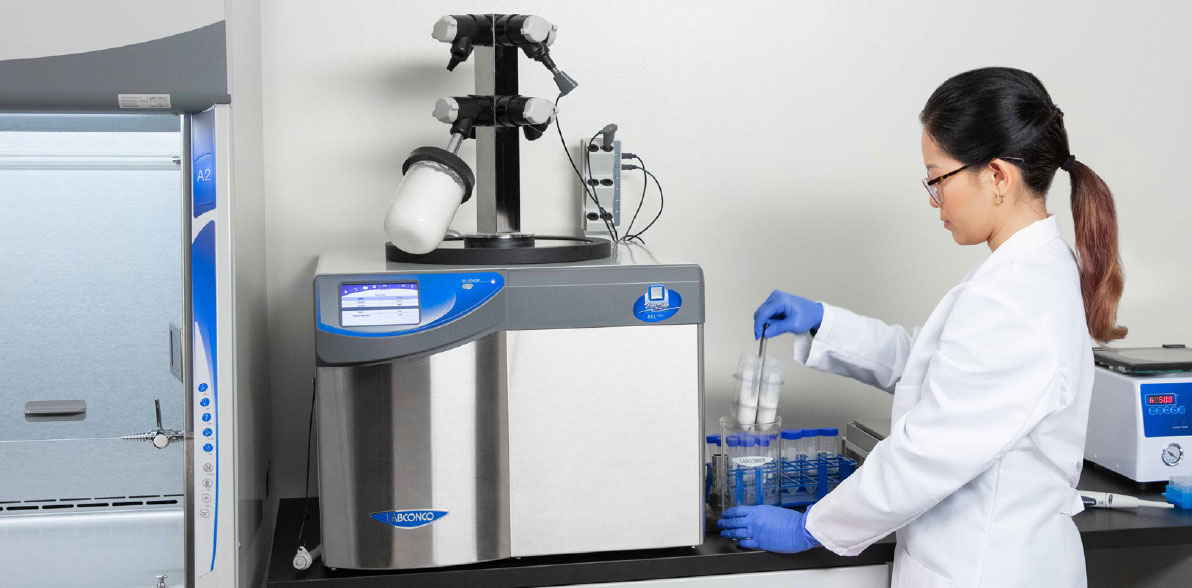

How to Purge a Vacuum Pump on a Labconco FreeZone Freeze Dryer

Procedural background and pump types

Over time, the oil in a vacuum pump can become contaminated causing it to become cloudy, accumulate particles or become discolored. The useful life of vacuum pump oil can be extended if the vacuum pump is operated or purged for an extended period after a freeze dry run. This allows contaminants to be purged from the hot oil.

To purge a vacuum pump, the inlet to the pump needs to be blocked off to prevent air from free flowing through the pump. If the freeze dryer has a purge valve, it will isolate the pump from the system.

If you do not have a purge valve, closing all sample valves on a dry freeze dry system will “dead head” the pump to block the free-flowing air. If the pump is operated at an elevated vacuum level (>10mBar), oil may be expelled from the pump and damage could occur.

Download the complete article to continue reading.

| chevron_left | Pedal to the Metal | Articles | Class II, Type C1 Biosafety Cabinet: Versatility, Safety & Savings Comparison | chevron_right |