Maintaining laboratory equipment during periods of inactivity: Vacuum Pumps and Cold Traps

The pandemic of 2020 has taught us many things. We were all forced, very unexpectedly, to live and work in unconventional ways. During these times, many issues came up in laboratories that were previously of little concern. For most labs, equipment is used routinely or continuously, and not much thought is given to what would happen if the equipment were to sit idle for an extended period. This article series will explain what can happen if equipment is left idle for long periods, how to prepare equipment for an extended period of inactivity, and how to restart equipment. In this three-part series, we will cover water purification systems and glassware washers, ventilated enclosures and equipment requiring the use of vacuum pumps.

See Part 1: Glassware Washers & Water Purification Systems

See Part 2: Ventilated Enclosures, Fume Hoods & Biosafety Cabinets

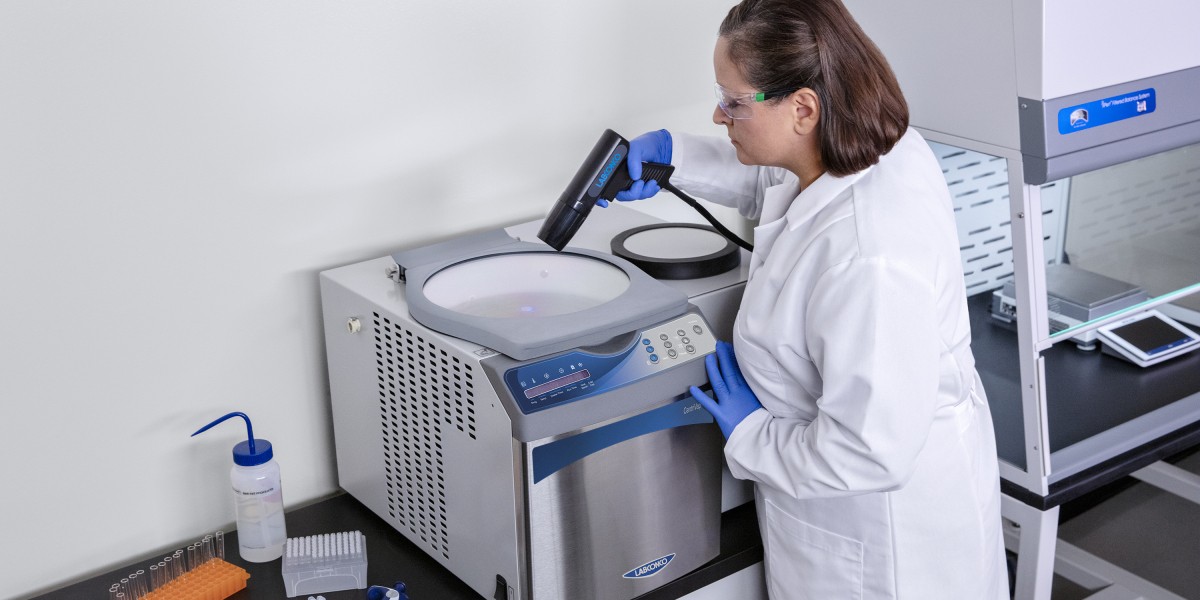

Freeze Dryers, concentrators, and vacuum evaporators all use vacuum pumps, either oil based or oil-free, and may also have an associated cold trap. This equipment requires the system be kept under negative pressure during evaporation/sublimation to remove moisture away from the sample. The vacuum pump ensures the vapors will move toward the vacuum pump either directly or through a cold trap to be condensed. For this article, we will focus on how to prepare vacuum pumps and cold traps for long periods of inactivity.

Vacuum Pumps

Rotary vane vacuum pumps should run for a short period after each use with the gas ballast open. This allows any vapor that may have reached the oil to evaporate and will prolong the life of the oil and the vacuum pump. If you are unsure about the status of your pump, you will want to do a purge. Under a closed system, fully open the gas ballast and run the pump for 30 minutes. Be sure to close the ballast after. If the oil has started to darken, we recommend changing the oil per the manufacturer’s instructions. These steps will help ensure that harmful vapor is not just mixed in your oil while the system is not in use.

Hybrid pumps also contain oil, but do not require oil changes as frequently as rotary vane pumps. This is because the vapor removed from the sample does not contact the oil. However; hybrid, diaphragm and scroll vacuum pumps can build up condensable vapor inside during use. A purge of these vacuum pumps can be done the same way as a rotary vane pump is purged and is recommended. We recommend running the pump under a closed system for 30 minutes with the gas ballast open. This will allow any trapped moisture to escape and help prevent corrosion inside the pump. If you are unsure of the status of your pump, we recommend running the pump under a closed system for 30 minutes with the gas ballast open before shutting down the system for long term. For the hybrid vacuum pump, we advise you check your oil and replace when needed.

Please refer to the manufacturer’s user guide for recommended use of the gas ballast and proper shut-down and maintenance procedures specific for your model.

Cold Traps

A cold trap is essentially a container that is mechanically cooled to anywhere from -50 to -105 degrees Celsius. The primary role of the cold trap is to remove any vapor that is coming off the sample from the air that is passing through it. As the vapor enters the trap, it is attracted to the colder surface of the trap and condenses. Over time, condensate can build up (typically around half the volume of the trap) before needing emptied or defrosted. If you plan on turning off your trap for an extended period, empty the trap following the manufacturer instructions and wipe clean with an appropriate cleaner. Following these simple steps now will ensure your system is ready to go when you return.

Should you have any questions regarding the proper use of your Labconco product, please contact us.

| chevron_left | Glassware Washer and Detergent – Synergy at its Finest | Articles | Lab Productivity & Optimization | chevron_right |