Maintaining your freeze dryer and vacuum pump

The most common complaint about freeze drying is loss in vacuum pressure. This loss is most often due to one of two things:

- A leak in the freeze dry system.

- An issue with the vacuum pump.

Have the right vacuum pump?

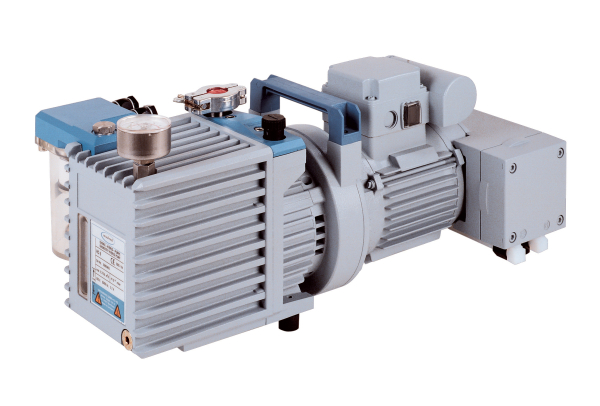

Because freeze drying requires an oil based rotary vane pump to maintain the depth of vacuum, it’s important to choose the right pump. A standard rotary vane pump works well with aqueous-based solutions. For solvents and acids, a more robust hybrid or combination pump is recommended. If the solvents should bypass the collector, or if the collector is not cold enough, vapors can migrate into the pump. This leads to shorter intervals needed between oil changes, and shorter effective pump life.

Because freeze drying requires an oil based rotary vane pump to maintain the depth of vacuum, it’s important to choose the right pump. A standard rotary vane pump works well with aqueous-based solutions. For solvents and acids, a more robust hybrid or combination pump is recommended. If the solvents should bypass the collector, or if the collector is not cold enough, vapors can migrate into the pump. This leads to shorter intervals needed between oil changes, and shorter effective pump life.

Have the right freeze dryer?

If you notice the oil in your freeze dryer is getting dirty quickly, make sure you have the correct freeze dryer for your application. See the article entitled “Need a Lyophilizer? Read this before you buy”.

If you notice the oil in your freeze dryer is getting dirty quickly, make sure you have the correct freeze dryer for your application. See the article entitled “Need a Lyophilizer? Read this before you buy”.

Need a secondary trap?

If you already have the correct lyophilizer, a secondary trap can also be used to protect the pump. And if you do not have the correct lyophilizer, a secondary trap may still help the situation.

Need another kind of trap?

For trace amounts of acids or solvents, a soda acid trap or activated carbon solvent trap can be placed between the freeze dryer and pump. If larger amounts are used, or if you’re experiencing melt-back, a dry ice trap or liquid N2 trap are recommended. Both traps act as a second collector, preventing melt-back and protecting the pump.

If doing the above steps does not fix the problem, below is a video on troubleshooting your freeze dryer. The video will walk you through the steps you need to take to get your freeze dryer up and running.

Freeze Dry Vacuum System Troubleshooting PDF

Provides instructions and illustrations to help solve vacuum leaks.

| chevron_left | Video: Intelli-Sense Multi-Speed Blower saves energy | Articles | Choosing the correct Cold Trap for your CentriVap | chevron_right |