Reducing laboratory fume hood energy consumption, even at 100fpm face velocity!

There is an ever increasing demand for laboratories to have a reduced impact on the environment, as well as a lower cost to operate. With this continuing push for reduced energy consumption in laboratories, lab planners, architects, engineers, and lab managers are leaving no stone unturned. One of the most powerful tools to reduce energy consumption is the implementation of High Performance Fume Hoods in the laboratory.

Most High Performance Fume Hoods achieve higher energy efficiency by simply requiring a lower face velocity. This makes sense, since the overwhelming majority of the cost to operate a fume hood comes from the cost to temper the laboratory room air that the fume hood simply pumps outside. If the hood has a lower face velocity, and still maintains a safe level of containment, the result is less tempered air leaving the lab, less newly tempered air entering the lab, and consequently a reduced operating cost.

However, there are a lot of laboratories that cannot take advantage of lowering the face velocity to conserve energy. Many organizations and agencies have written face velocity requirements of 100 fpm. For instance, in the state of California, CalOSHA notes that “the exhaust system shall provide an average face velocity of at least 100 feet per minute…” 1. Those individuals charged with reducing energy consumption may overlook the design of the fume hood if they feel they are limited, or if they are opposed, to reducing the face velocity.

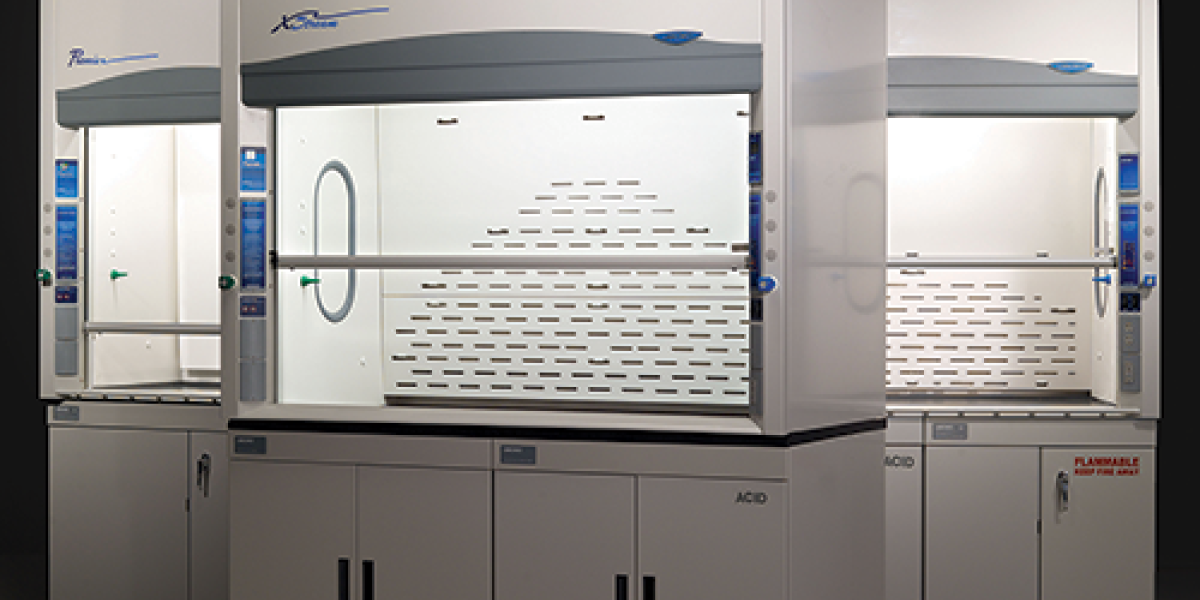

The Labconco® Protector® XStream® solves this issue by reducing the required volumetric rate (CFM) without requiring a reduction in the face velocity. Modern fume hoods rely on a variety of air entry points to ensure robust dilution and containment, and in some cases, proper functionality on a constant volume mechanical system. In addition to the large face opening (sash opening) on the hood, the sum of these area openings is what is critical to the fume hood’s total volumetric rate requirements. By minimizing the requirements for airflow through openings other than the sash opening, the total volumetric rate is minimized. This is achieved without compromising containment, the user’s access to the hood interior, or the hood’s ability to work on a constant volume mechanical system.

An average six foot fume hood operating at a 100 fpm face velocity, with the sash fully open, will consume 1250 cubic feet of expensive tempered air every minute, or as much annual energy as three average American households. Because of the volumetric rate minimization approach to the design, a 6’ Protector XStream fume hood, with the same usable opening, operating at 100 fpm with the sash fully open, consumes 1150 CFM—100 CFM less than the average hood. This reduction in airflow results in a lifetime savings of $10,500 per fume hood.*

Regardless of the mechanical system design, desired sash opening height, or face velocity requirements, the Protector XStream was engineered to deliver maximized containment with the lowest possible energy consumption.

* Based on average annual dollars per CFM of $7.00; fume hood operating 24 hours a day and 5 days per week (6240 hours per year). Average annual dollars per CFM range from $5.00 to $12.00 depending on geographic location. Assumes a 15 year lifespan.

1CalOSHA, Subchapter 7. General Industry Safety Orders, Group 16. Control of Hazardous Substances, Article 107. Dusts, Fumes, Mists, Vapors and Gases, §5154.1. Ventilation Requirements for Laboratory-Type Hood Operations, (c) Ventilation Rates

| chevron_left | Inclination™ Technology: features that reinforce what humans are inclined to do | Articles | Scratching an itch: Dandruff could be definitive | chevron_right |