What are the biosafety cabinet classes?

Laboratory hoods, biosafety cabinets and enclosures may look similar, but they are all very different in function and are each engineered for specific applications. Understanding how each of your ventilation devices are designed to work will help keep your laboratory personnel safe. Let’s talk about one of the most functional units of the life science laboratory: the biosafety cabinet (BSC).

BSCs are designed to handle hazardous pathogenic materials, among other biohazards, and are used regularly in various types of laboratories ranging from basic research to high containment. Sometimes biosafety cabinets are simply referred to as tissue culture hoods, laminar flow hoods, or chemo hoods in a pharmacy. Every BSC is categorized by a specific biosafety class: Class I, Class II or Class III. How do you know which option is best for your lab? In this article we will break down the different BSC classes, discuss how different types of BSCs operate and the recommended practices for each type based on current safety standards.

Each BSC is classified by how the cabinet protects the user and their samples, and defines the processes and applications each cabinet is designed to handle. In certain cases, some BSC classes have subtypes (e.g. Type A, Type B, and Type C). Before we dive deeper into the classes and types of biosafety cabinets, its important to understand where these definitions and guidelines come from.

Around the world, different organizations and standards are used to define the cabinet requirements for manufacturing and use. Safety officers, biosafety cabinet manufacturers and certifiers all rely on select sources to ensure safe operational procedures are in place within laboratories that use biosafety cabinets. This includes proper manufacturing to applicable design standards. For this article, we are using biosafety cabinet definitions, classifications and use parameters outlined by the Centers for Disease Control Guide: Biosafety in Microbiological and Biomedical Laboratories (BMBL) and by the NSF International (NSF) Standard - Biosafety Cabinetry Certification: NSF/ANSI 49. In North America, these standards define how biosafety cabinets can be used within the laboratory and how biosafety cabinets must function. Other important design standards such as EN 12469 (Europe), YY 0569 (China), AS 2252 (Australia), and others are largely derived from NSF/ANSI 49 and are covered by the below descriptions.

Class I

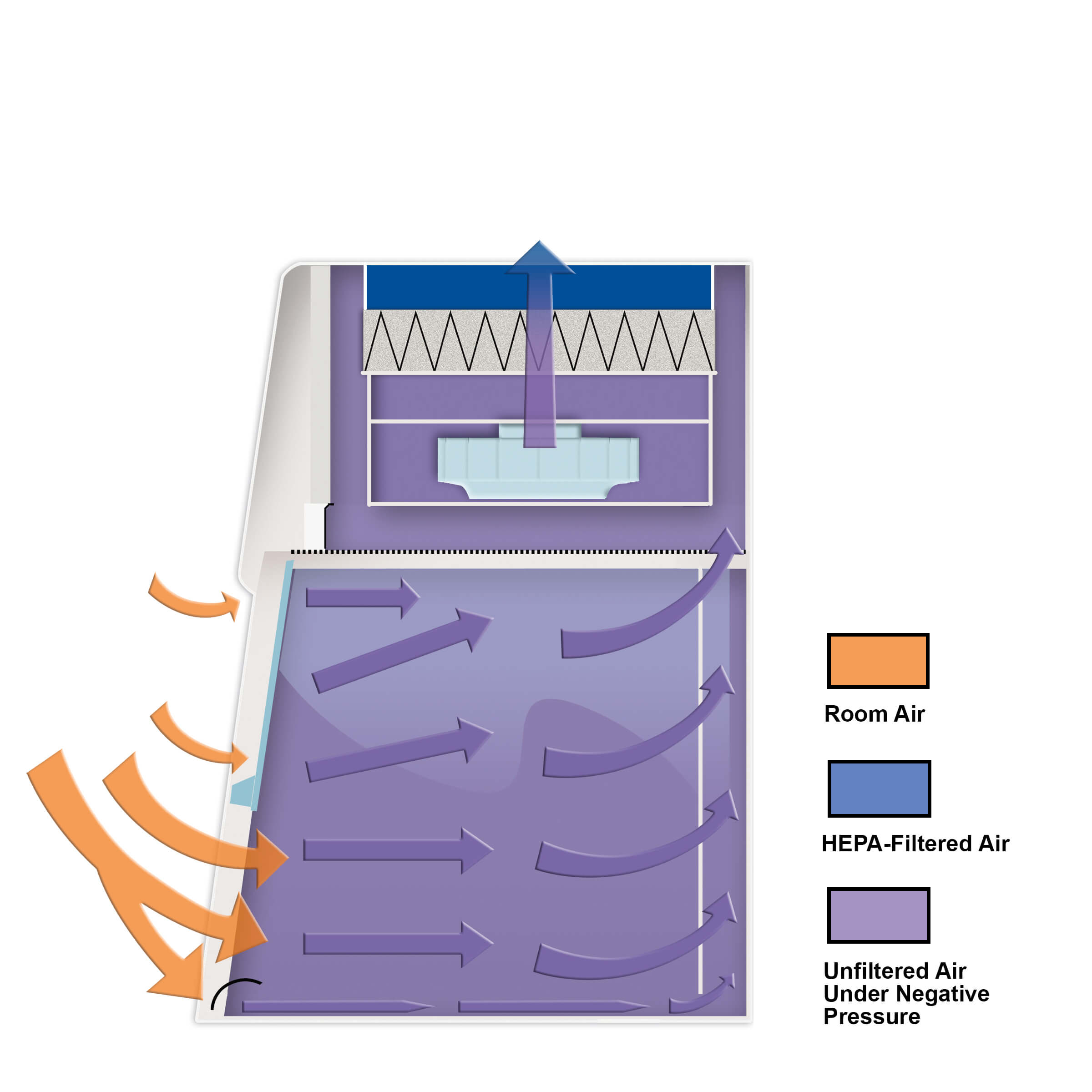

A Class I cabinet Class I biosafety cabinet is defined as a ventilated cabinet that provides personnel and environmental protection. Class I BSCs are designed with an open front with inward airflow (personnel protection) and HEPA-filtered exhaust air (environmental protection). They pull room air through the front of the cabinet and across the worksurface, away from the operator (similar to a fume hood), and use a HEPA filter at the exhaust outlet. They commonly recirculate air back to the laboratory, but can be externally exhausted if needed. For applications requiring external exhaust, Labconco offers canopy style exhaust connections that allow for use of the internal blower with a remote exhaust blower. Class I biosafety cabinets are safe for use with agents classified as Biosafety Level (BSL) 1, 2, 3 or 4, in conjunction with other protective measures required for these biosafety levels.

Class II

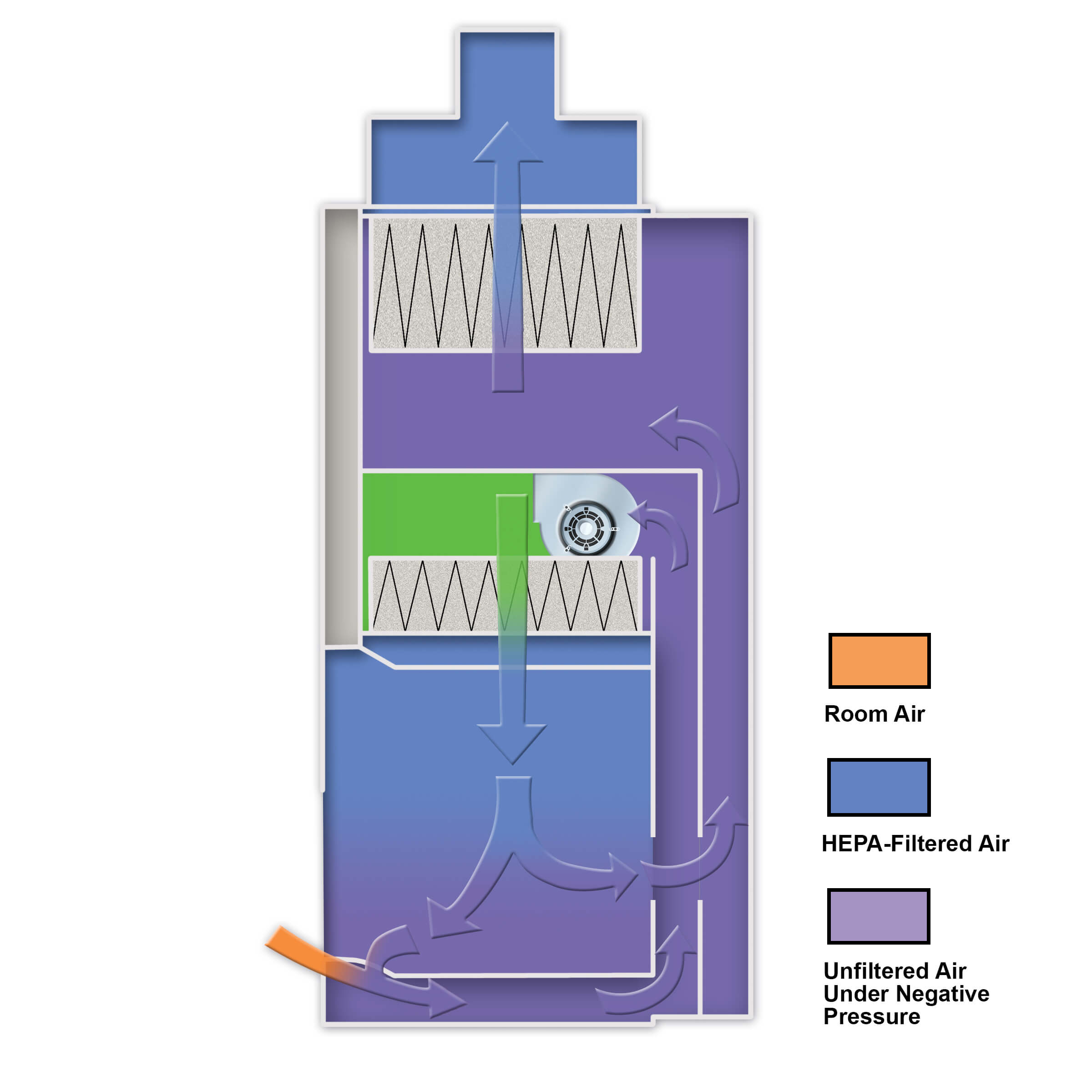

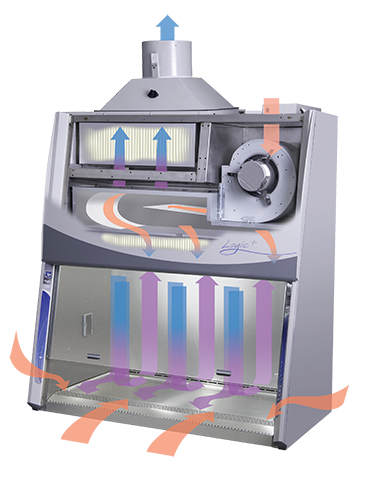

A Class II cabinet is defined as a ventilated cabinet for personnel, product and environmental protection, often used for microbiological work or sterile pharmacy compounding. In some labs, these containment hoods are referred to as cell culture or tissue culture hoods. In pharmacy settings, these hoods are referred to as chemo hoods. Class II BSCs are designed with an open front with inward airflow (personnel protection), downward HEPA-filtered laminar airflow (product protection) and HEPA-filtered exhaust air (environmental protection). These cabinets are further differentiated by types based on construction, airflow and how they interface with exhaust systems — A1, A2, B1, B2 and C1. All Class II BSCs require all biologically contaminated ducts and plenums to be under negative pressure or surrounded by negative pressure ducts and plenums. This provides a fail-to-safe feature that protects the user even in the event of a plenum failure. Type B2 cabinets take this a step further, requiring all biologically contaminated ducts and plenums to be under negative pressure or surrounded by directly exhausted negative pressure ducts and plenums. Type C1 cabinets provide even more protection by maintaining containment from biological and chemical hazards during building exhaust failures. Like Class I cabinets, Class II cabinets are safe for work using agents classified as BSL 1, 2, 3 or 4, in conjunction with other protective measures required for these biosafety levels.

A Class II cabinet is defined as a ventilated cabinet for personnel, product and environmental protection, often used for microbiological work or sterile pharmacy compounding. In some labs, these containment hoods are referred to as cell culture or tissue culture hoods. In pharmacy settings, these hoods are referred to as chemo hoods. Class II BSCs are designed with an open front with inward airflow (personnel protection), downward HEPA-filtered laminar airflow (product protection) and HEPA-filtered exhaust air (environmental protection). These cabinets are further differentiated by types based on construction, airflow and how they interface with exhaust systems — A1, A2, B1, B2 and C1. All Class II BSCs require all biologically contaminated ducts and plenums to be under negative pressure or surrounded by negative pressure ducts and plenums. This provides a fail-to-safe feature that protects the user even in the event of a plenum failure. Type B2 cabinets take this a step further, requiring all biologically contaminated ducts and plenums to be under negative pressure or surrounded by directly exhausted negative pressure ducts and plenums. Type C1 cabinets provide even more protection by maintaining containment from biological and chemical hazards during building exhaust failures. Like Class I cabinets, Class II cabinets are safe for work using agents classified as BSL 1, 2, 3 or 4, in conjunction with other protective measures required for these biosafety levels.

Type A2

A Class II, Type A2 biosafety cabinets are the most common type of BSC used today and have replaced the use of Type A1 cabinets. Type A2 cabinets must maintain a minimum average inflow velocity of 100 fpm through the sash opening. A portion of the inflow air is exhausted while another portion is recirculated within the cabinet. Type A2 BSCs typically exhaust HEPA-filtered air back into the laboratory, but can be connected to laboratory exhaust systems through a canopy connection for handling odorous samples or limited amounts of volatile chemicals. The recirculated, HEPA-filtered downflow air creates an ISO 5 environment within the work area that protects the samples from external contaminants. The laminar (unidirectional) downflow air pattern helps prevent cross contamination within the cabinet, between samples.

When limited amounts of volatile chemicals are required, both NSF 49 and BMBL advise the unit shall be connected to an external exhaust system via a canopy style exhaust connection that will provide an audible and visual alarm within 15 seconds of an exhaust failure. It’s advised to never use a direct-connect or hard ducted connection when working with hazardous chemicals. Canopy vented Type A2 cabinets may be used for work with limited amounts of volatile chemicals if deemed appropriate by a chemical risk assessment. For the risk assessment, it’s important to note that a Type A2 cabinet does recirculate some of the exhaust air within the cabinet, which could lead to an accumulation of chemical vapors.

Type B1

Class II, Type B1 biosafety cabinets must maintain a minimum average inflow velocity of 100 fpm through the sash opening and must be connected to a building exhaust system. They have HEPA-filtered downflow air composed mostly of uncontaminated recirculated inflow air and exhaust most of the contaminated downflow air through a dedicated duct after passing through a HEPA filter. Type B1 cabinets are safe for work involving limited amounts of volatile chemicals and trace amounts of radionuclides, as long as the work is done in the rear portion of the cabinet behind the smoke split. The rear portion is not marked or well-defined, and is ever-changing as the BSC’s filters load, making this type of cabinet unsafe for all but the most well-trained users.

Type B2

A Class II, Type B2 cabinets must maintain a minimum average inflow velocity of 100 fpm through the sash opening and require a dedicated exhaust system and dedicated remote blower for each cabinet. Because of this, they are sometimes referred to as 100% Exhaust or Total Exhaust cabinets. They have HEPA-filtered downflow air drawn from the laboratory (not recirculated from the cabinet exhaust) and exhaust all inflow and downflow air out to the atmosphere after filtration through a HEPA filter. Type B2 cabinets are suitable for work involving limited amounts of volatile chemicals and trace amounts of radionuclides as an adjunct to microbiology applications. Although Type B2 BSCs offer protection when using higher volumes of chemicals within the cabinet, they require complicated exhaust configurations and consume large amounts of air to function. As a result, Type B2 cabinets have the highest installation and operational costs of any Class II BSC.

Type C1

A Class II, Type C1 cabinet must maintain a minimum average inflow velocity of 100 fpm through the sash opening, like Type A2 and B2 cabinets. Type C1 cabinets are unique in that they can operate as either a Type A cabinet when in recirculating mode or a Type B cabinet when connected to remote exhaust. Type C1 cabinets can be changed from one mode to the other by connecting or disconnecting the exhaust and having the cabinet recertified. When in exhausted Type B mode, Type C1 cabinets clearly define the areas where users can work safely using delineated areas for storage, and a central work area with dedicated direct exhaust for use with chemical vapors, radionuclides, or chemotherapy preparations. In addition to this flexibility, Type C1 cabinets do not require a dedicated exhaust run or dedicated blower, making exhausting the cabinet easier and more cost-effective. The ease of exhausting, combined with the reduced air requirements for exhaust on top of the flexibility make the Class II, Type C1 cabinet an easy choice for new projects and laboratories that require flexibility.

Class III

A Class III cabinet is defined as a totally enclosed, ventilated cabinet with leak-tight construction and attached rubber gloves for performing operations in the cabinet. These cabinets have a transfer chamber with interlocked doors that allow for sterilization of materials before entering/exiting the glove box. Materials can also be taken in and out through a dunk tank filled with a disinfecting solution. The cabinet is maintained under negative pressure and supply air is drawn in through HEPA filters. The exhaust air is treated with either double HEPA filtration or single HEPA filtration followed by air incineration and then exhausted outside. Class III cabinets are safe for agents classified as BSL 1, 2, 3 or 4, in conjunction with other protective measures required for these biosafety levels, however they are most commonly found in BSL 3 and BSL 4 laboratories, dubbed cabinet laboratories.

If you have any questions regarding which biosafety cabinet is appropriate for your application, please contact us or reach out on our Live Chat.

| chevron_left | The rundown-What type of water should I use in my application? | Articles | Ever wonder what happened to the Class II Type A/B3 Biosafety Cabinet? | chevron_right |