Fume hood liner requirements

The standard for general laboratory hood construction, performance, and design is Underwriters Laboratory 1805, Standard for Laboratory Hoods and Cabinets. Requirements include nonflammable interiors made from corrosion and chemical-resistant materials. Labconco fume hoods comply with UL 1805 and carry the ETL Listed Mark as proof of compliance.

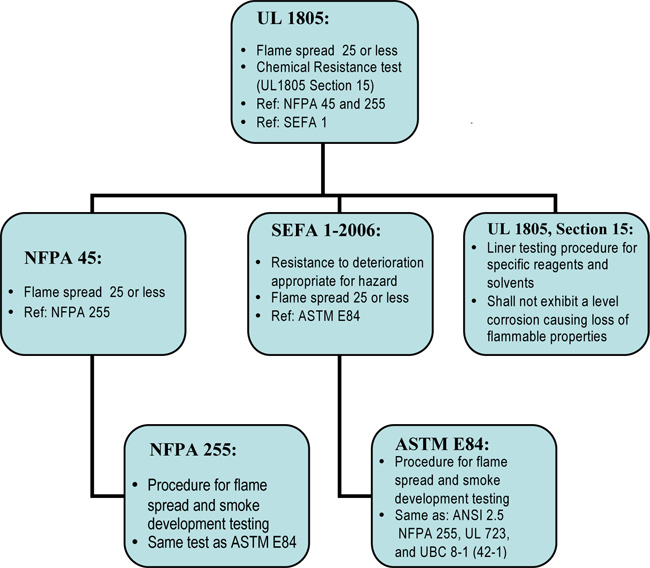

UL1805 stipulates that hood interiors must have a flame spread of 25 or less in accordance with NFPA 255 testing methods, and per NFPA 45, Fire Protection for Laboratories Using Chemicals, shall have automatic fire protection if the flame spread is greater than 25. UL 1805 also notes SEFA 1, Recommended Practices for Laboratory Fume Hoods, as a general reference for its development.

Additionally, Section 15 of UL 1805 gives a clear fume hood liner testing procedure for specific reagents and solvents. Below, each of these are individually addressed and explained how Labconco complies with them. This section of the document specifies (28) chemicals that should be applied to liner test samples, covered with a watch glass, left for 30 minutes, cleaned, and then examined under seven power magnification.

This test is often referred to as the “watch glass test.” The liner material “…shall not exhibit visual evidence of corrosion, including cracking, blistering or softening to a degree which would cause a significant loss of desired physical and flammability properties.”

SEFA 1 notes that interior materials shall be “…resistant to the chemical fumes, vapors and condensation particulate that may collect…”, but does not give specifics on how to grade materials based on their resistance to certain chemicals; nor give a standardized list of chemicals to test. Because of SEFA’s limited direction on chemical resistance requirements, UL 1805, Section 15, is the sole standard on this topic.

SEFA 1 notes that interior materials shall be “…resistant to the chemical fumes, vapors and condensation particulate that may collect…”, but does not give specifics on how to grade materials based on their resistance to certain chemicals; nor give a standardized list of chemicals to test. Because of SEFA’s limited direction on chemical resistance requirements, UL 1805, Section 15, is the sole standard on this topic.

However, SEFA 1 is quite clear on the flammability requirements for fume hood interiors; “Liner materials should be flame retardant, self-extinguishing and have a flame spread rating of 25 or less in accordance with ASTM-E84.” They go on to note that if the liner material cannot meet this standard, an automatic fire suppression system should be used.

ASTM E84 is a standardized test method for determining the surface burning characteristics of building materials. The purpose is to determine the burning behavior by observing the flame spread along the specimen.

ASTM E84 is a standardized test method for determining the surface burning characteristics of building materials. The purpose is to determine the burning behavior by observing the flame spread along the specimen.

ASTM E84 is published under other designations, including ANSI 2.5, NFPA 255, UBC 8-1 (42-1), and UL 723.

NFPA calls for all laboratory hoods to “…have a flame spread index of 25 or less when tested according to NFPA 255…” and follows by noting that greater flame spreads are allowed as long as the hood is “…provided with automatic fire protection…”

NFPA calls for all laboratory hoods to “…have a flame spread index of 25 or less when tested according to NFPA 255…” and follows by noting that greater flame spreads are allowed as long as the hood is “…provided with automatic fire protection…”

NFPA 225 is a method of testing the surface burning characteristics of building materials and, as noted above, is identical to ASTM E84.

Labconco’s standard panelized liner is composed of fiberglass reinforced polyester (FRP), manufactured by Roechling-Glastic Corporation, and is called Wesliner. This liner is used on our Protector XL, XLE, and XStream fume hoods. Wesliner's specification states it has undergone extensive chemical testing and exceeds UL 1805 requirements and flame spread of 25.

The Protector Premier® Fume Hood uses a molded fiberglass reinforced polyester liner. The “watch glass test” was performed on this liner material, yielding similar, but slightly superior results to a standard FRP liner. This enhanced performance is due primarily to the gel coat layer directly exposed to reagents and solvents.

The liner also regularly undergoes ASTM E84 testing conducted by Intertek Testing to verify the flame spread is 25 or less, and copies of this test report are available upon request. Labconco’s Chemical Resistance Guide is a great comparison of 316 stainless steel to FRP. For more information, visit the following websites: UL Intertek ASTM NFPA SEFA Labconco

| chevron_left | Fume hood liner selection process | Articles | Labconco offices holiday closures | chevron_right |