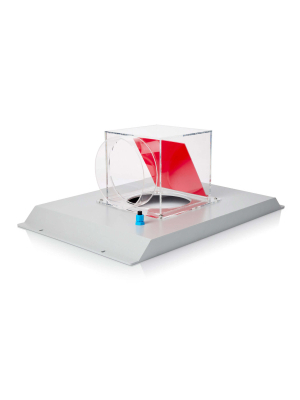

EN 12469 Certified ReVo™ Class II, Type A2 Microbiological Safety Cabinets provide personnel, product and environmental protection from biohazardous agents and hazardous particulates. Other appropriate applications include work with antineoplastic drugs, genetic material, and additional substances that generate hazardous airborne particulates. All models are EN 12469 compliant with additional certification by TÜV Nord.

These biological safety cabinets are designed to discharge HEPA-filtered exhaust air directly into the laboratory, or into an exhaust system through the optional Canopy Connection. When canopy-connected, the biosafety cabinets may be used for applications involving minute quantities of volatile toxic chemicals and tracer amounts of radionuclides as an adjunct to microbiological research. During operation, room air is drawn into the inlet grill. The air in the plenum beneath the work surface is a mixture of unfiltered room air and air that has just passed through the work area. This contaminated air is drawn by the blower through the back plenum of the cabinet, where approximately 70% of the air is recirculated through the supply HEPA filter and back over the work area. The balance of the contaminated air is discharged to the environment after passing through the exhaust HEPA filter.