Labconco Vacuum Pump Buyer's Guide: Finding the Perfect Pump for Your Needs

Choosing the right vacuum pump for your lab can be a daunting task. With Labconco's diverse range of pumps, navigating the different options requires understanding your specific needs and matching them to the pump's capabilities. This guide provides the knowledge necessary to make an informed decision, ensuring you select the perfect Labconco pump for your laboratory workflow.

Step 1: Define Your Application

Identify the primary application your pump will serve. Common applications include:

Freeze Drying (Lyophilization): Requires pumps with deep vacuum capabilities and effective water vapor handling.

Evaporation and Concentration: Pumps should achieve moderate vacuums and handle vapors efficiently.

Glove Box Environment: Requires pumps with higher flow rates and tolerance f or aggressive or corrosive gases.

Step 2: Consider Key Pump Characteristics

After determining your application, evaluate the following crucial pump characteristics:

Vacuum Level: Measured in millibar (mBar), it indicates the lowest pressure the pump can achieve. Deep vacuums are needed for lyophilization, while moderate vacuums suffice for evaporation and concentration. Choose a pump with an ultimate vacuum lower than your application's target.

Pumping Speed: Measured in L/min, it defines how quickly the pump removes gas from your chamber. Higher speeds are ideal for rapid processes.

Chemical Compatibility: Some pumps require solvent-resistant models to handle harsh chemicals effectively.

Noise Level: Consider noise constraints, especially if your lab is near colleagues. Labconco offers reduced-noise options such as our dry scroll pump with a silencer attachment.

Maintenance Needs: Some pumps require routine oil changes and component replacement, while others operate oil-free for lower maintenance.

Step 3: Explore Labconco's Pump Options

We offer five main pump types:

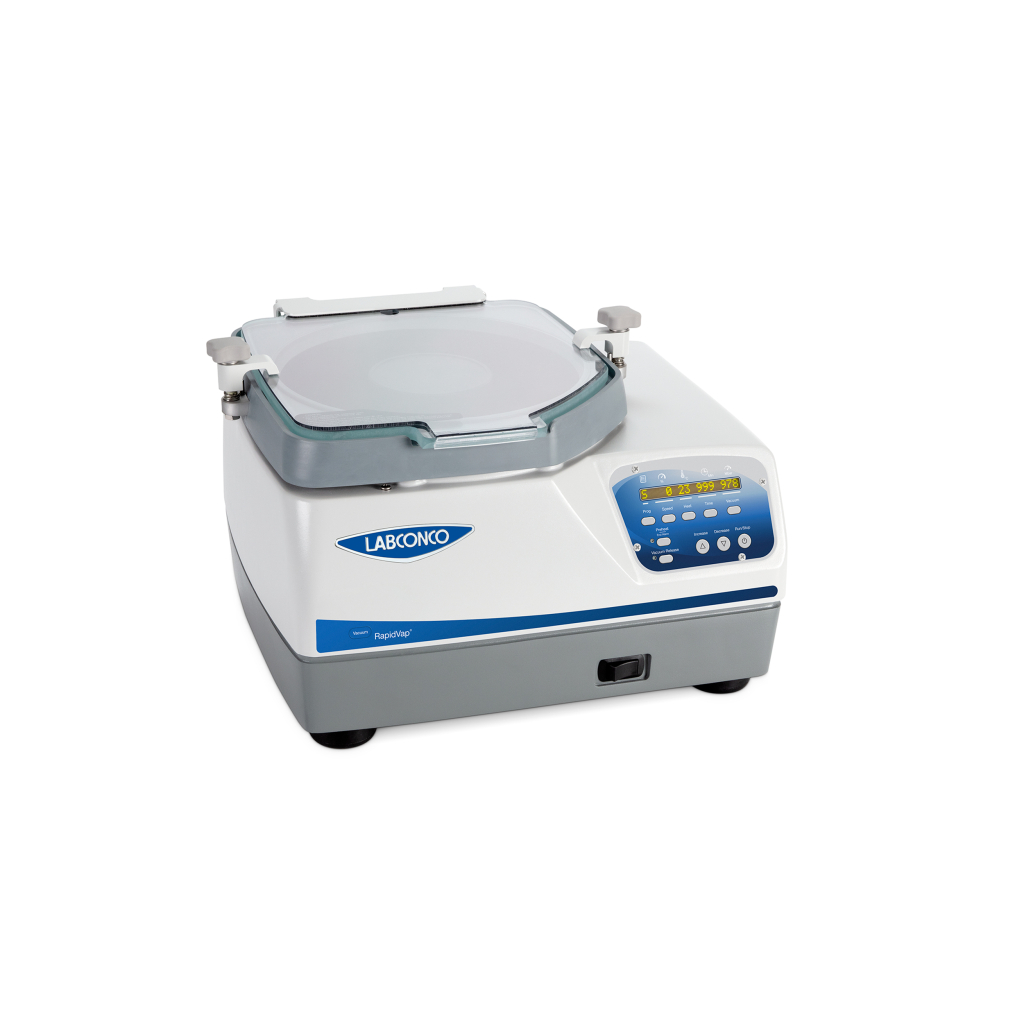

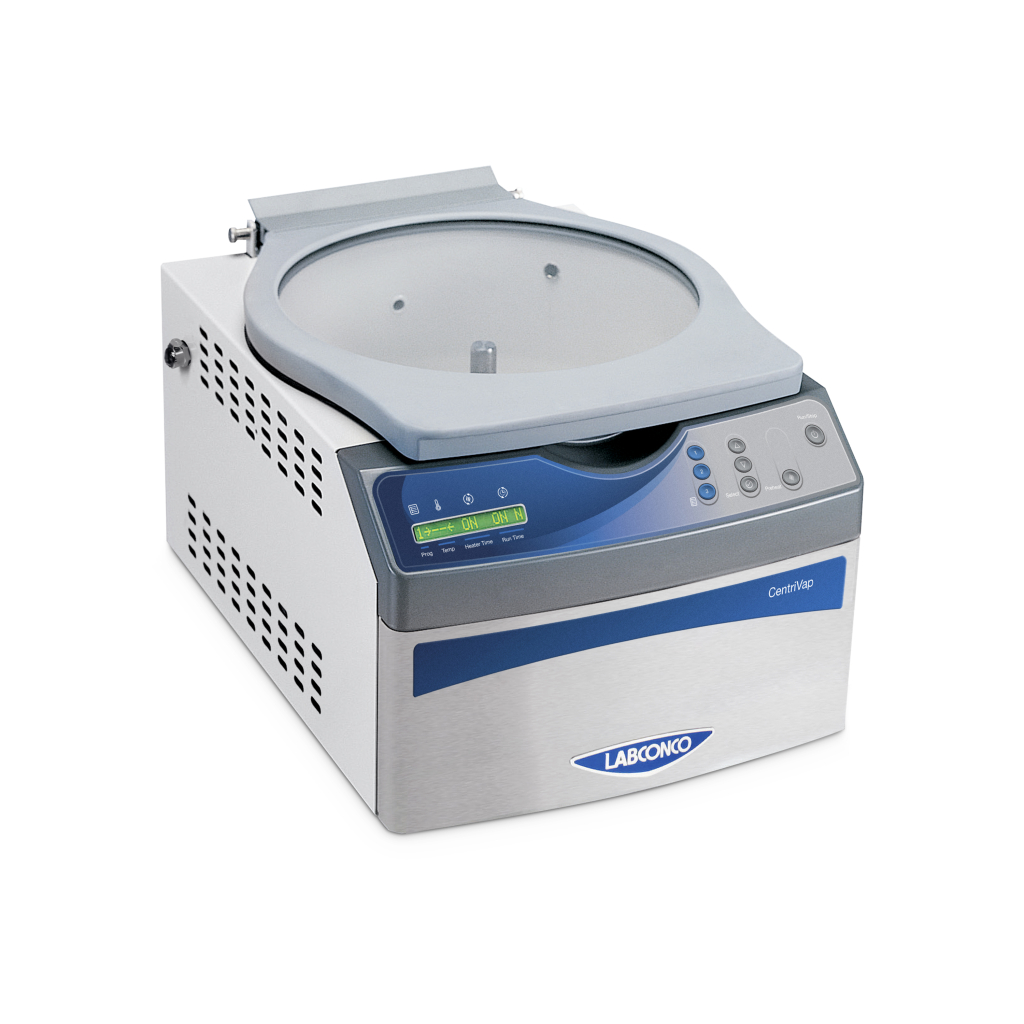

Diaphragm Vacuum Pump: An oil-free vacuum pump with PTFE-coated wetted parts for superior corrosion resistance and minimal maintenance. The vacuum depth ranges from 1.5 mBar to 7 mBar depending on the model, making it ideal for applications involving CentriVap® Centrifugal Concentrators and RapidVap® Vacuum Evaporation Systems. Diaphragm pumps are not recommended for freeze drying due to insufficient pressure capabilities. Labconco offers two diaphragm pump versions based on application needs.

Diaphragm Vacuum Pump for Drying Train: This single cylinder, oil-free diaphragm pump is specifically designed for drying train circulation in Precise® Controlled Atmosphere Glove Boxes, Protector® Combination Glove Boxes, and Protector® Controlled Atmosphere Glove Boxes. Displacement capacities range from 42 to 63 L/min with an ultimate vacuum of 206 mBar.

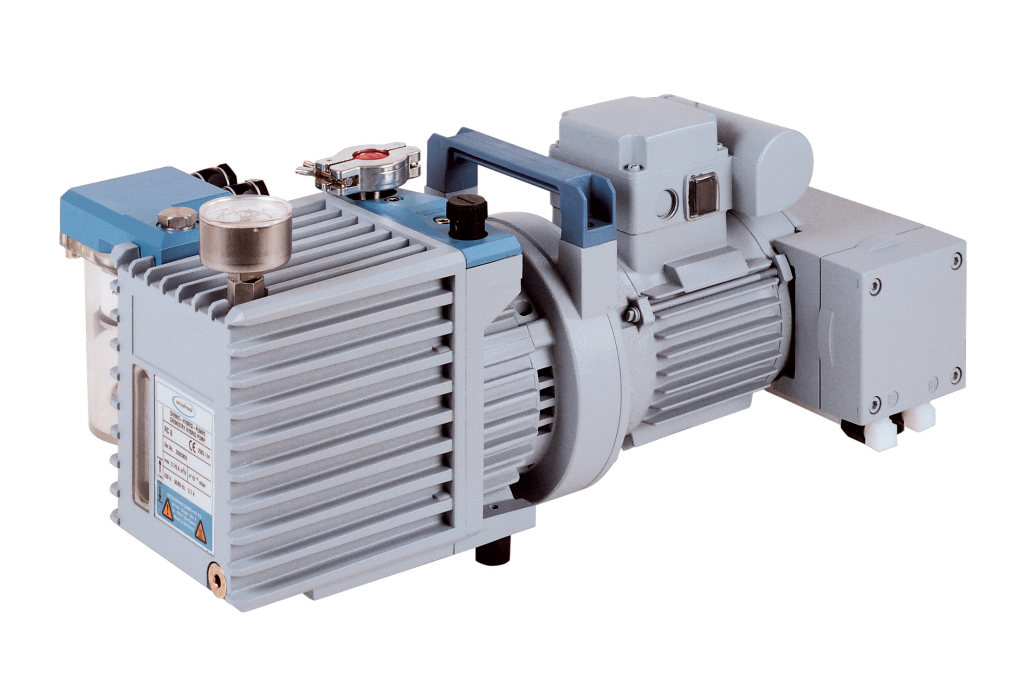

Rotary Vane Vacuum Pump: A cost-effective, general purpose pump achieving a deep vacuum of 2 x 10-3 mBar, suitable for a wide range of laboratory applications. Labconco offers two versions with different displacements, or pumping speed. Regular oil monitoring, routine oil changes and post-run purging are recommended to extend the pump’s lifespan. The pumping speed and vacuum levels are well-suited to maintain lyophilization conditions.

Chemically Resistant Rotary Vane Vacuum Pump: Designed for harsh chemical applications, this pump achieves a deep vacuum of 2 x 10-3 mBar and features continuous acid neutralization and oil filtration, ensuring high performance in caustic conditions. Regular oil monitoring, routine oil changes, and post-run purging are recommended for extended pump life. The pumping speed and vacuum levels are well-suited to maintain lyophilization conditions.

Hybrid Vacuum Pump: Combines rotary vane and diaphragm pump mechanics into one design, utilizing an integrated diaphragm pump to maintain negative pressure in the oil body of a rotary vane pump. This reduces condensing vapor within the pump, prolonging oil life and reducing corrosion risks. The hybrid pump handles chemicals and corrosives better than standard rotary vane pumps while achieving pressures as low as 2 x 10-3 mBar. Regular oil monitoring, semi-routine oil changes and post-run purging are recommended for extended pump life. The pumping speed and vacuum levels are well-suited to maintain lyophilization conditions.

Scroll Vacuum Pump: Available in two oil-free versions achieving ultimate vacuum pressures of either 7 x 10-3 mBar or 2 x 10-2 mBar. These pumps are ideal for lyophilization conditions without requiring regular oil changes. Purging the pump after each use is recommended to remove any condensed vapors that may have accumulated during use.

Step 4:Verify Equipment Compatibility

RapidVap® Vacuum System: Diaphragm pumps are recommended for the RapidVap system. An optional cold trap or liquid trap is advised to condense vapors and protect the pump. Venting the pump’s exhaust through a chemical fume hood is recommended for handling potentially harmful vapors that may bypass the vapor trap. For more efficient solvent recovery, an optional trapping valve can be used for further reducing vapor exposure, but it must be paired with a cold trap.

CentriVap® Vacuum System: Any of Labconco’s vacuum pumps can be used with the CentriVap system, but unintended results may occur. If considering a rotary vane pump or hybrid pump, a cold trap is strongly recommended to trap vapors and protect the pump and laboratory from potentially corrosive vapors. The lower vacuum levels of oil-based and scroll pumps may result in samples freezing and undergoing sublimation rather than evaporation. The CentriVap system can be paired with a rotary vane, hybrid or scroll pump to perform evaporation and lyophilization functions simultaneously. However, a diaphragm pump is recommended for most applications.

Freeze Drying (Lyophilization): The rotary vane, hybrid and dry scroll pumps are suitable for freeze drying applications. Here are the recommendations based on sample type:

- Primarily Aqueous Samples: Use rotary vane, chemically resistant rotary vane, hybrid or scroll pumps.

- Aqueous/Corrosive/Solvent Samples: Use chemically resistant rotary vane, hybrid or scroll pumps.

|

|

Diaphragm Pump |

Rotary Vane Pump |

Chemically Resistant Rotary Vane |

Hybrid Pump |

Scroll Pump |

|

CentriVap® |

X |

X- if freeze drying |

X- if freeze drying |

X- if freeze drying |

X- if freeze drying |

|

Freeze Dry |

|

X |

X |

X |

X |

|

RapidVap® |

X |

|

|

|

|

|

Glove Box |

X |

X |

X |

X |

X |

Step 5: Consult Labconco Resources and Experts

Utilize our comprehensive resources for further guidance:

- Product Selection Tools: Our website offers interactive tools to match your application with suitable pumps.

- Reference Library: Access articles, white papers and application notes providing in-depth information on specific pump types and applications.

-

Contact Us: Our expert team is available to offer personalized advice based on your unique needs and budget. Reach out to us via:

- Toll-free call: (800) 821-5525 for application support

- Let Us Contact You

- Live Chat

By understanding your application, key pump characteristics and Labconco's diverse options, you can confidently select the ideal pump for your laboratory. Remember, investing in the right pump ensures efficient workflows, reliable performance, and ultimately, successful research outcomes.

| chevron_left | Hydrogels and Aerogels: Creating the ‘Coolest’ Next-Gen Materials Through Lyophilization | Articles | Riboflavin Coverage Test | chevron_right |