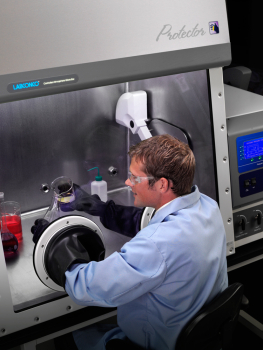

What to know about gloveboxes

As a Product Manager of 26 years, I have seen glovebox usage increase for a growing number of applications. Scientists, engineers, manufacturers, and facility managers have started using new terms for these devices in an effort to better define and categorize specific glovebox applications. The terms isolator, isolator glovebox, glovebox isolator, and barrier isolator are now commonly used to describe a glovebox and its functions. Unfortunately, expedient terminology usually falls short of defining the operational requirements for any specific glovebox. In general terms, there are two types of gloveboxes: isolator gloveboxes that are filtered by ventilation, and controlled atmosphere gloveboxes.

Isolator gloveboxes

The term isolator most often implies the use of high efficiency particulate air (HEPA) or ultra low penetration air (ULPA) filtration for a glovebox application. Isolation can mean keeping something out or keeping something in. Is that "something" hazardous to humans, or are humans hazardous to the "something"? What is the application goal? Answers to these questions, as well as those that follow, can help determine the precise glovebox needed for a specific application.

The term isolator most often implies the use of high efficiency particulate air (HEPA) or ultra low penetration air (ULPA) filtration for a glovebox application. Isolation can mean keeping something out or keeping something in. Is that "something" hazardous to humans, or are humans hazardous to the "something"? What is the application goal? Answers to these questions, as well as those that follow, can help determine the precise glovebox needed for a specific application.

Will both inlet and exhaust air streams require particulate filtration? For applications where the materials inside the box need to be protected from common environmental particulates, inlet filtration is required. If those materials generate hazardous particulates, exhaust airflows must also be filtered.

Should HEPA or ULPA filters be used?

Both HEPA and ULPA filters provide International Organization for Standardization (ISO) Class 5 sterile air. ULPA filters provide a better capture profile if nano-particulates are a concern.

Will the exhaust air need to be vented to the outside?

If the exhaust contains harmful fumes or gases, exhausting to the outside is required. Particulate filters do not trap these contaminants.

Should the internal glovebox pressure be positive, negative, or adjustable?

Hazardous particulates inside a glovebox should be kept under negative pressure. Maintaining a sterile environment inside a glovebox may require positive pressure.

What can be done, then, if the material inside needs to be kept sterile and is hazardous?

To help answer this question, leak tightness should be reviewed. ISO10648-2 (ANSI, 1994) classifies containment enclosures based on leak tightness and provides methods for checking the leak rate of the glovebox. Many gloveboxes are extremely leak-tight and safety concerns regarding positive/negative pressure operations often become a non-issue.

Should the filtered airflow maintain an internal sterile air volume condition?

Air volume sterility is not the same as surface sterility. Diluting the internal air volume with sterile air can ultimately produce a sterile air volume, but does not mean the surfaces inside the glovebox are sterile.

Does the air volume and the internal glovebox itself need to be entirely sterile?

In order to maintain a total sterile environment, the airflow within a glovebox should be laminar. The glovebox must also be connected to a vaporous hydrogen peroxide (VHP) system. The VHP system, when used correctly, can ensure surface sterility within the glovebox before operations begin. Gloveboxes for this application can be quite complicated and costly.

Is sterility the correct condition? Or is a decontaminated environment the real operational goal?

The answer to this question can be found in many different private and government organization standards such as those provided by the U.S. Food and Drug Administration (FDA), U.S. Pharmacopeial Convention (USP), Controlled Environment Testing Association (CETA), etc.

As this review of product application questions indicates, searching for an isolator is an involved process. Many factors must be taken into consideration before a glovebox for a specific application can be selected.

Controlled atmosphere gloveboxes

Controlled atmosphere gloveboxes also have many not-so-descriptive names including dry boxes, inert boxes, nitrogen boxes, low oxygen and/or moisture boxes, hypoxia boxes, and anaerobic boxes. All of these gloveboxes have one thing in common: They typically are sufficiently leak-tight to provide some level of control over the internal gas atmosphere using a series of valves connected to a purified compressed gas source. The specific contaminant ranges and the required operation gases are the two most important details that must be communicated in any controlled atmosphere glovebox discussion.

Controlled atmosphere gloveboxes also have many not-so-descriptive names including dry boxes, inert boxes, nitrogen boxes, low oxygen and/or moisture boxes, hypoxia boxes, and anaerobic boxes. All of these gloveboxes have one thing in common: They typically are sufficiently leak-tight to provide some level of control over the internal gas atmosphere using a series of valves connected to a purified compressed gas source. The specific contaminant ranges and the required operation gases are the two most important details that must be communicated in any controlled atmosphere glovebox discussion.

In order for a controlled atmosphere glovebox to function, the internal ambient atmosphere gas contaminants must be removed and replaced with an alternative or purified gas. There are two methods of internal chamber purification. In a constant flush system, a continual flow of inert gas is required. In a glovebox that uses an evacuation/refill method, positive pressure gas and a negative pressure vacuum allow the main chamber of the glovebox to be evacuated and subsequently refilled with the inert gas.

The appropriate purified gas depends on the application, but the most common gases are the inert gases, such as nitrogen and argon. In some applications, such as those performed in hypoxia or anaerobic gloveboxes, standardized gas mixtures are required.

For some controlled atmosphere gloveboxes, the only contaminant removal system used is the gas evacuation and refill operation. Oxygen and moisture levels are reduced to 1% to 10%, and operations are completed within a normal eight-hour day. More sophisticated controlled atmosphere gloveboxes use a recirculating oxygen and/or moisture removal system along with the initial evacuation and refill operation to achieve and maintain extremely low (≤1 ppm) concentration levels. These accessory systems, which can be recharged when the oxygen/moisture removal catalysts become expended, are required to compensate for constant contaminant permeation occurring through the gloves regardless of the glovebox internal pressures.

While some controlled atmosphere gloveboxes create inert gas atmospheres with oxygen and moisture contamination levels maintained at ≤1 ppm, other applications, such as those performed in hypoxia gloveboxes, require oxygen levels of 200 ppm or higher. Still other applications, such as long-term product stability assays, require oxygen and/or moisture levels to reach 1% (10,000 ppm) or higher.

Simple labels are not enough to convey the entire scope of operation and design requirements for a glovebox system. No matter what a glovebox is called, be prepared to specifically define application goals and requirements. Matching a glovebox to a well-defined application is easy. Working with guesses and looking for a single glovebox to cover all possible outcomes is costly in both time and money.

This article originally appeared in Bioresearch Online Newsletter, February 11, 2013.

| chevron_left | Reducing Laboratory fume hood energy consumption, even at 100fpm face velocity! | Articles | University of California, Berkeley makes Logical connection | chevron_right |